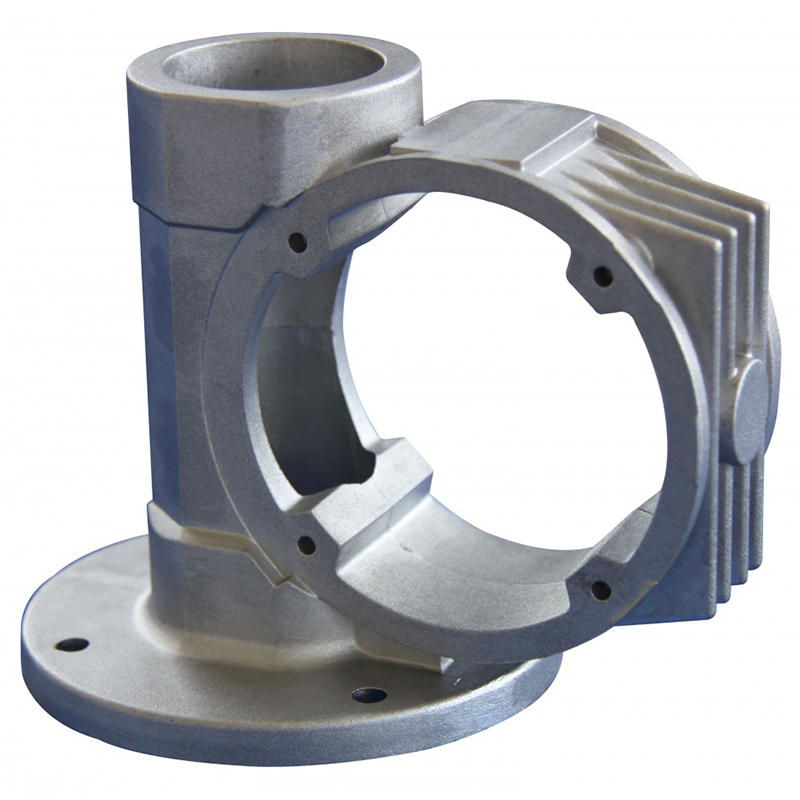

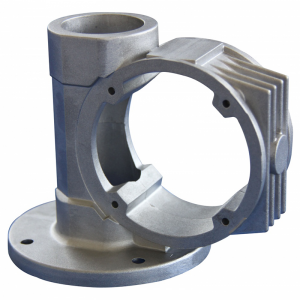

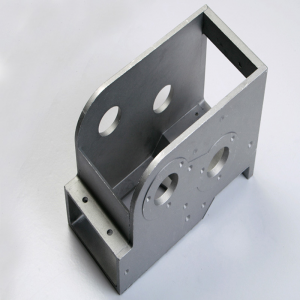

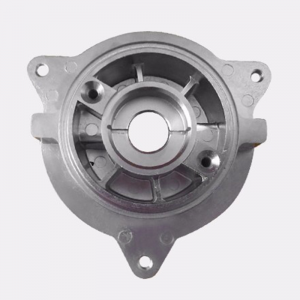

OEM Metal Die Processus Sample Production

Singula

| Item | Descriptio |

| Processus Technologiae | Amissa cera mittentes processus Processus vitrei solutum Silica processus eiectio Die mittentes processus Arena processus fundendi plus Precision CNC Machining Superficiem treatment |

| Praesto Material | (1) ferreum griseum, ductile ferrum, porcum ferreum |

| (2) chalybs carbonis, chalybs immaculata, stannum chalybe | |

| aluminium, aluminium, aluminium, A380, aluminium | |

| (4) Spodium, aes, aes, aes etc | |

| pondus dolor | 0.02-50 KGS |

| MOQ | 500 Pieces |

| tolerantia | ±0.02mm |

| Testis | Tres apparatus mensurae coordinare ad probandum. |

| Certification | ISO9001:2015 |

| Standard | ISO, DIN, AISI, ASTM, BS, JIS, etc. |

OEM Material

Obsideri ejectio: ASTMA148-class80-40, ASTMA148-class80-50, A572GR60, AISI316, Steel, ST52, S355, GS-52.3, ASTMA48-class30B, CK45, 1.7218-25CrMo4

Sand Ia: GGG50, GGG30, ASTMA48-class25B, 42CrMo4, C22, Ductile iron65-45-12, AlCuMgpbF34, EN-JIS-D-7, EN1563, EN10293-GE300, HT200, DIN17205-GS-25CrMo4

Die Jactus:C1040, A356, A380, AISI12

Advantages of Metal Die Casting

1. Partes metallicae facere potest cum figuris implicatis, adumbrationibus perspicuis, parietibus tenuibus et cavis profundis.

2. Disiectio altam habet accurationem dimensivam et bonam permutabilitatem.

3. Maximum efficiens productio et massa productio.

4. Securus utor frusta musiva.

5. Maximum materiae utendo rate.

Products categories

-

Phone

-

E-mail

-

whatsapp

whatsapp

-

WeChat

-

Top